Post-Probe Processing Tools

The demands made on semiconductor manufacturers by their customers and product applications, specifically in the automotive and medical sectors, are such that the manufacturers are being driven to find more effective ways of screening product and filtering out weak and unreliable parts, as early in the manufacturing process as possible. Not only does this result in significant cost savings for the manufacturer, but also and perhaps more importantly it ensures a higher quality product for the customer.

In recent years companies have implemented post-probe processes that are designed to target known fail modes and potential quality issues.

The WSC supports two post-probe processes i.e. ‘Automated Visual Inspection’ and ‘Maverick Die Elimination’.

The Post-Probe Processing Tools enable the real-time monitoring of the post-probe processes, providing visibility and detailed information of the progress of each of the individual stages from start to completion.

Post-Probe Integration

The WSC provides the ability to integrate post-probe processing in the form of Maverick Die Elimination (MDE) and Automatic Visual Inspection (AVI).

The electrical test results are merged with the results of the post-probe processes prior to ink or in readiness for inkless assembly.

Additional bad die identified by either the MDE and/or the AVI analysis will be highlighted and displayed in white as flashing die. This dynamic feature enables engineers and production staff to review the end result of all post processing before the product is committed for ink, and can be used as a tool to disposition material that has resulted in what is deemed to be unacceptable yield loss.

In addition, the WSC provides the ability for MDE analysis to be performed retrospectively under engineering control where electrical test results can be retrieved from archive. This important feature can be used by engineering to assess the impact of MDE product recipes prior to release or as an engineering tool to investigate problems highlighted at final test.

Post-Probe Inking

The WSC provides the ability to define product specific yield trigger limits, such that product will go on hold for engineering review should the AVI and/or the MDE post-probe processes cause significant yield loss.

The WSC provides the option for engineering to submit product for reanalysis using different product recipe conditions to assess the impact of changes to MDE parameters, facilitating the turnaround of changes required in the event of shifts in the fabrication process.

These dynamic features enable engineering and production personnel to review the end result of all post-probe processing before the product is committed for ink.

Post-Probe Viewing Tool

Once wafer probe is complete, the WSC passes the test results onto each of the post-probe processes for further analysis, the results of which are merged and any subsequent fails are recorded and downgraded.

The WSC retains the original test results plus the results of each of the individual post-probe processing steps, and provides the ability to load the resulting colour wafer maps for review, highlighting the die that failed subsequently due to the post-probe processing.

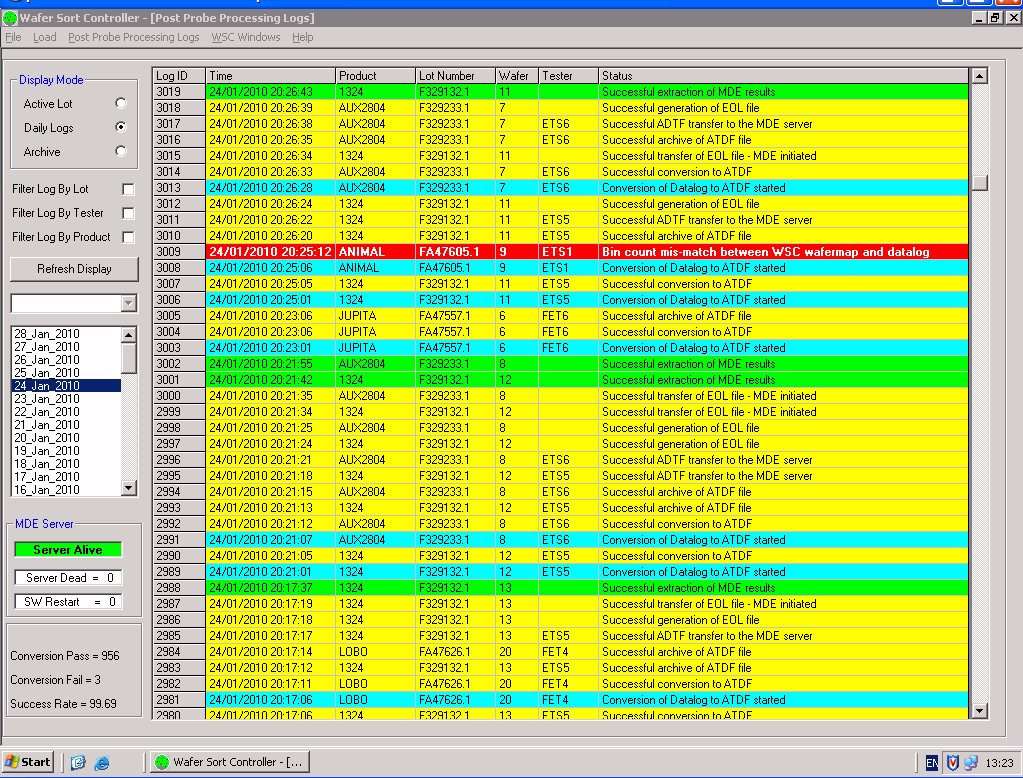

In addition, the WSC keeps a full log and archive of all post-probe activity for traceability purposes, an extract of which is shown below.