Wafer Sort Controller

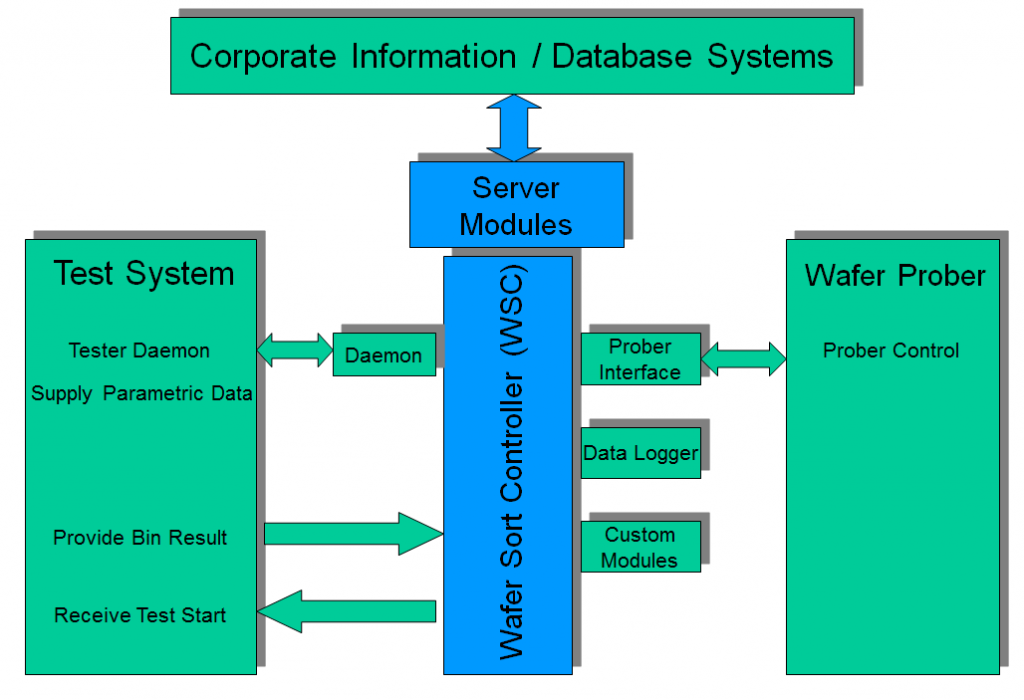

The Wafer Sort Controller (WSC) is a cost effective wafer probe test cell control system that manages the complete wafer test process and production flow. This generic tool enables the streamlining of the wafer probe production process by adding modern features to existing wafer probers to upgrade and expand their capabilities, such as: –

- Real-Time Graphical Wafer Mapping

- Off-Line Inking

- Inkless

- Multi-Site Probing

- Real-Time Production Controls

- Real-Time Production Monitoring

- Wafer Thumbnails

The WSC provides a generic graphical user interface that is independent of the tester and prober type, and is designed to take full control of the wafer probe process providing optimized control maps, increased flexibility, improved productivity and overall efficiency, hence maximizing tester utilisation.

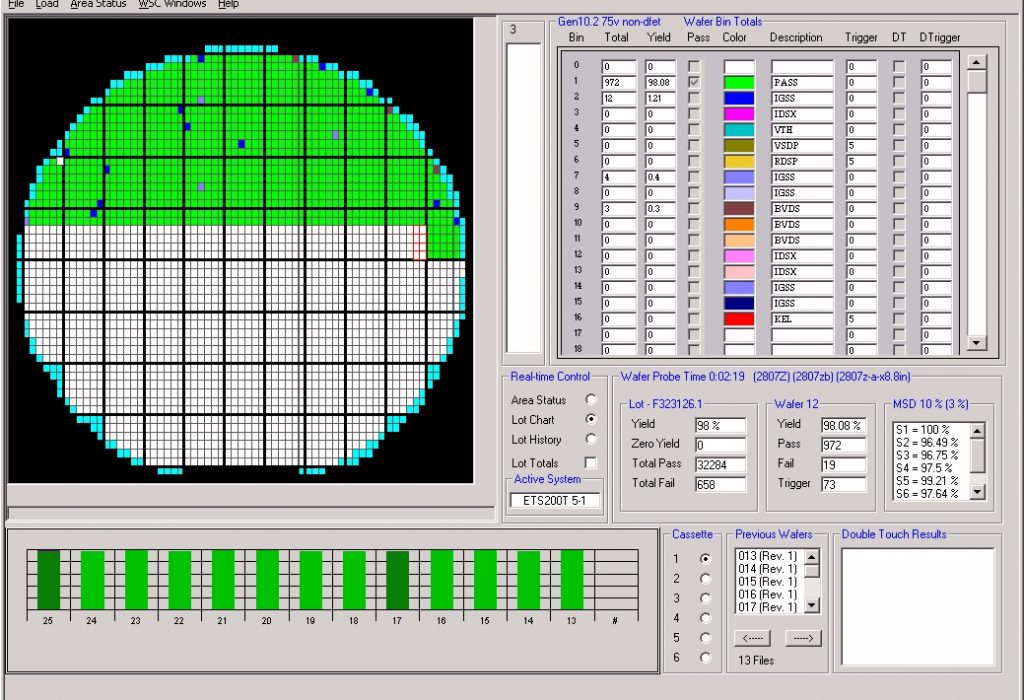

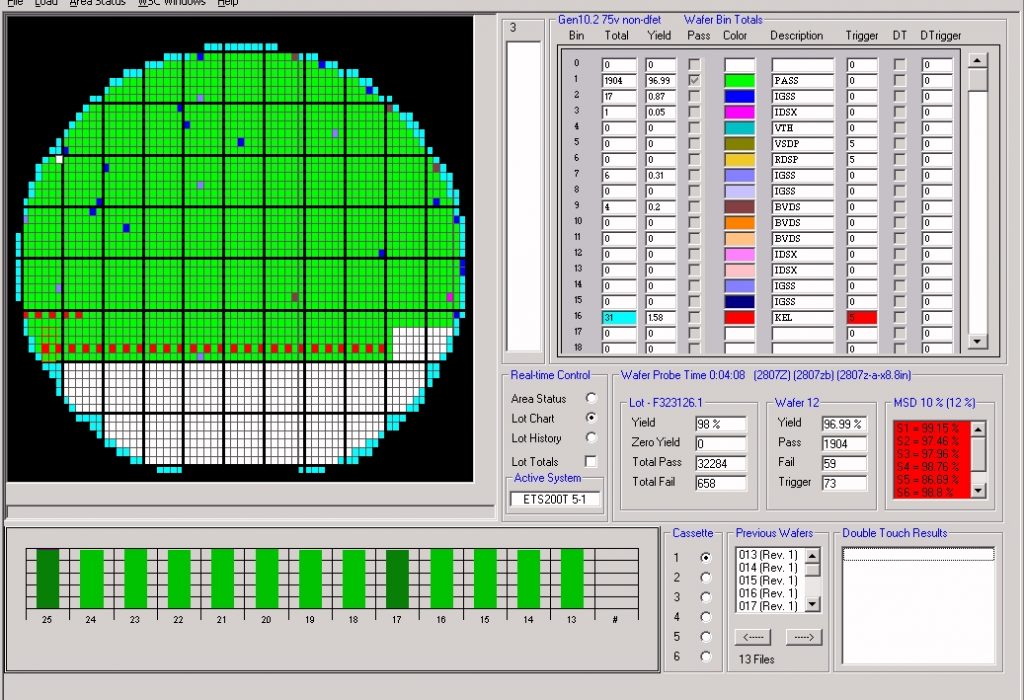

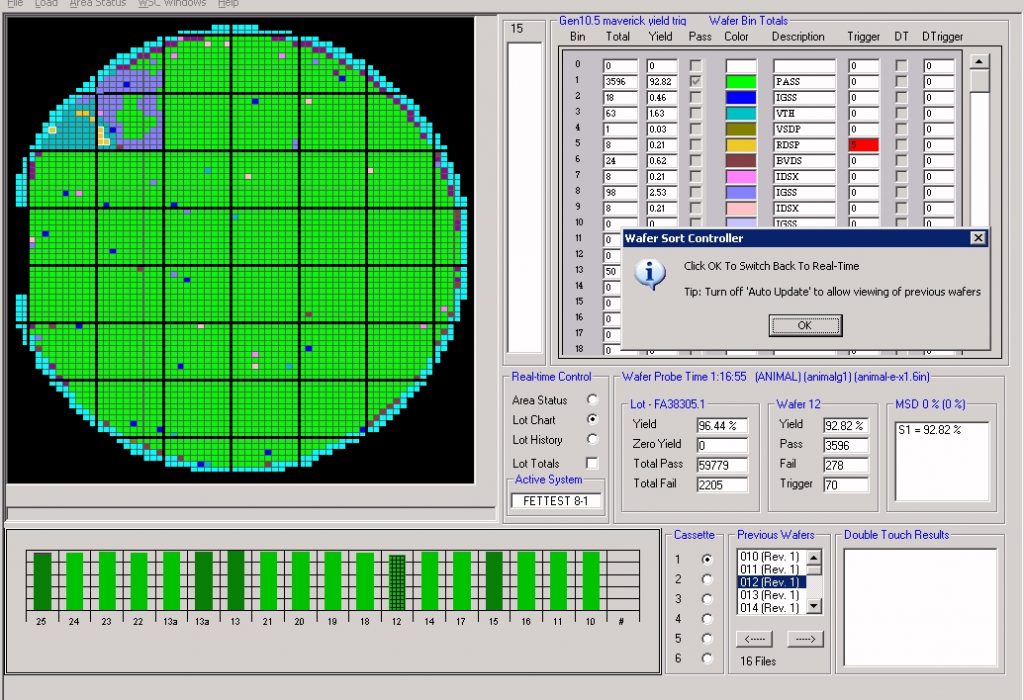

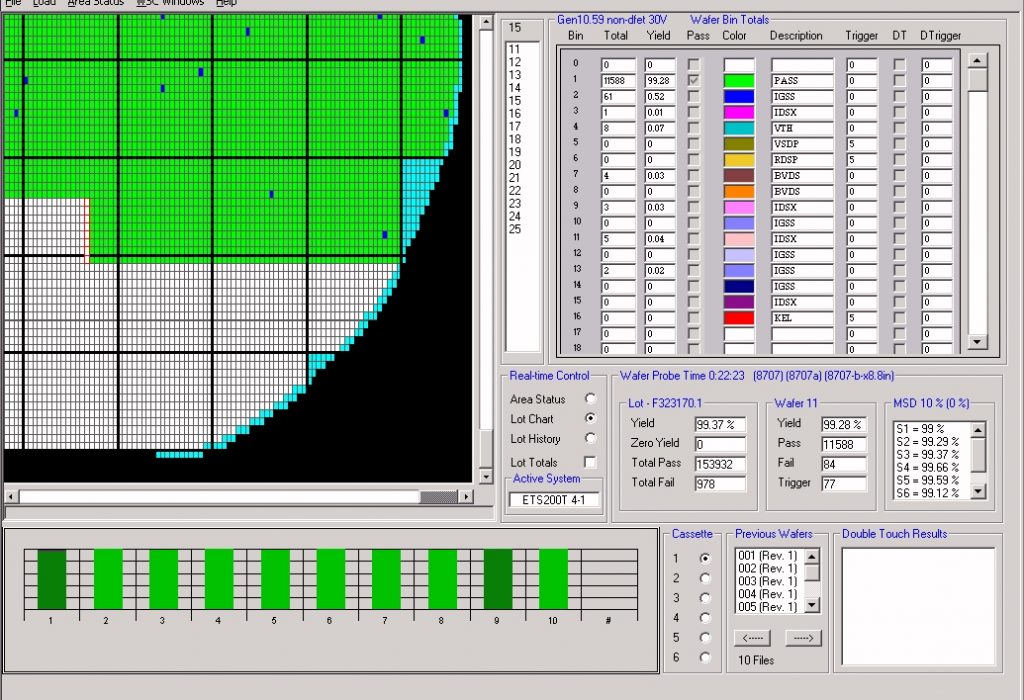

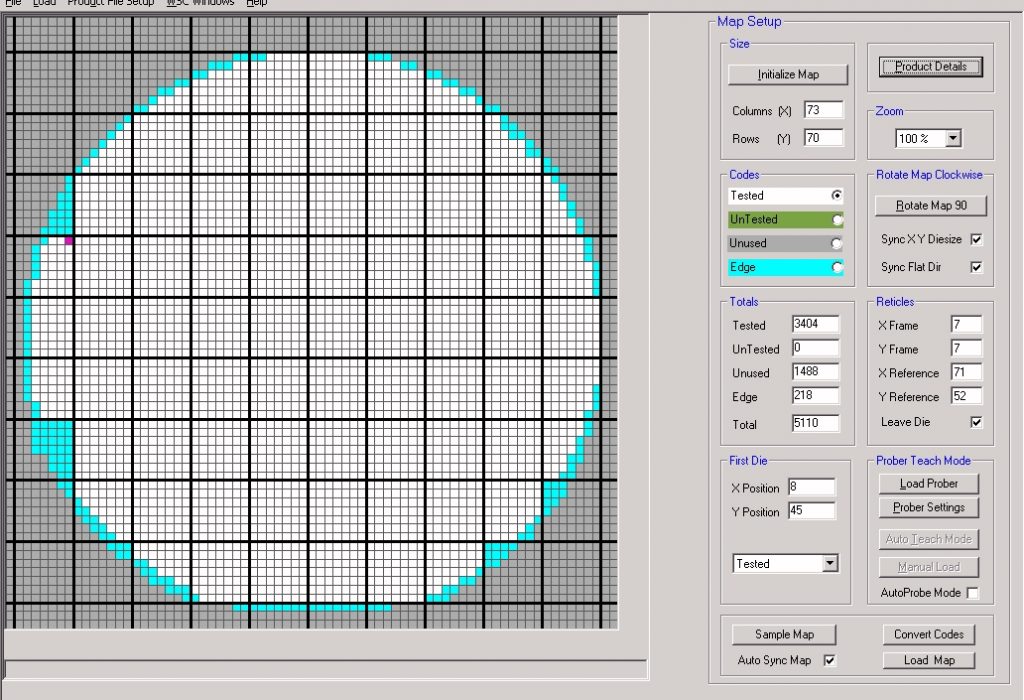

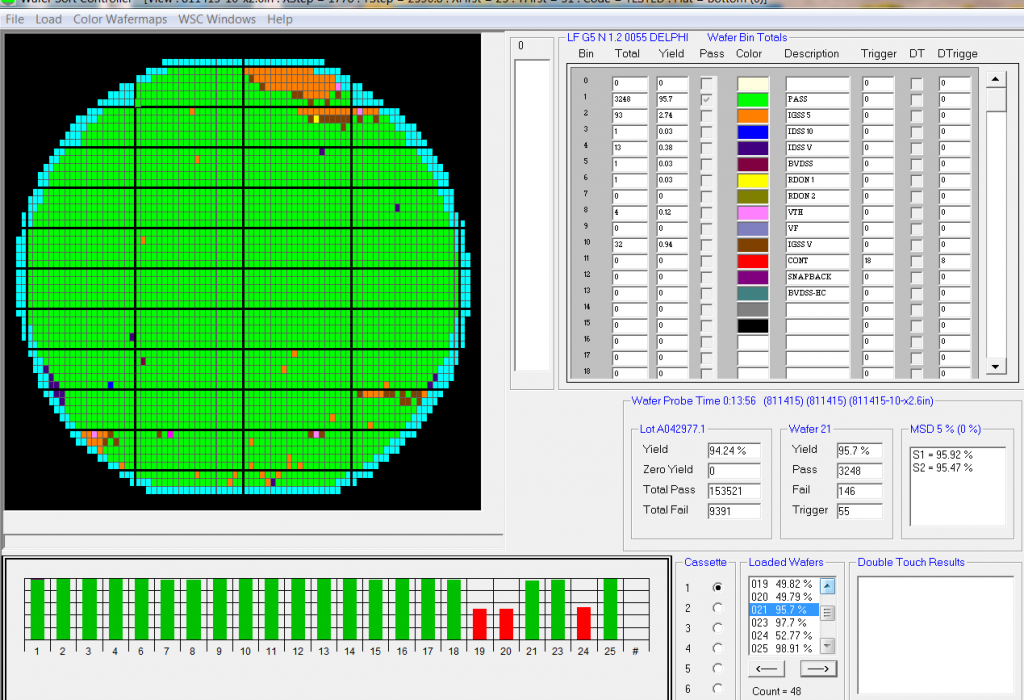

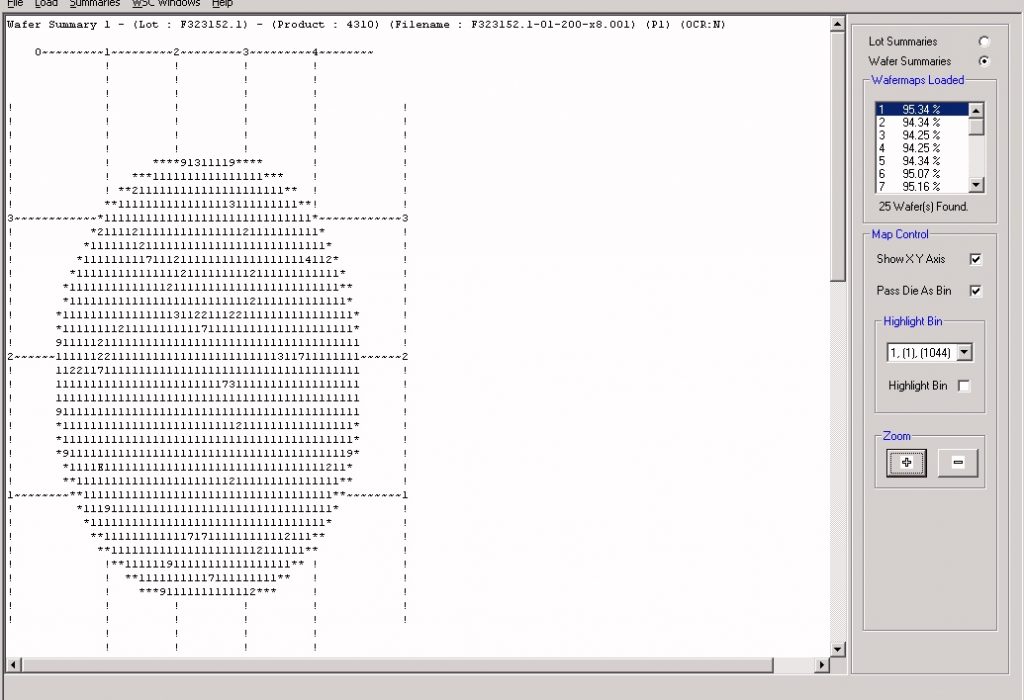

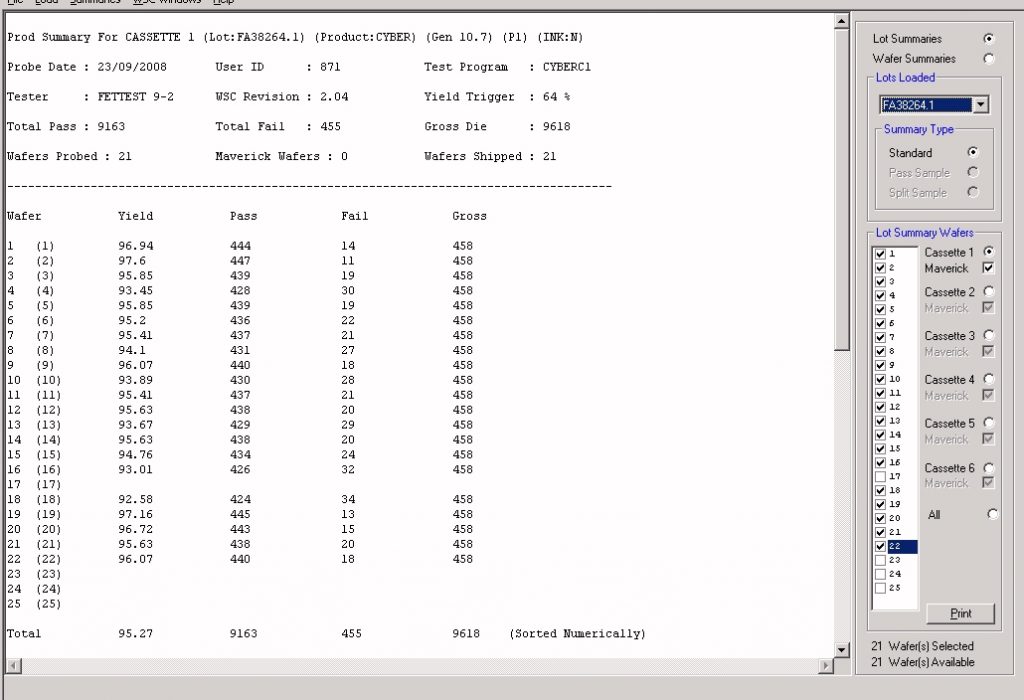

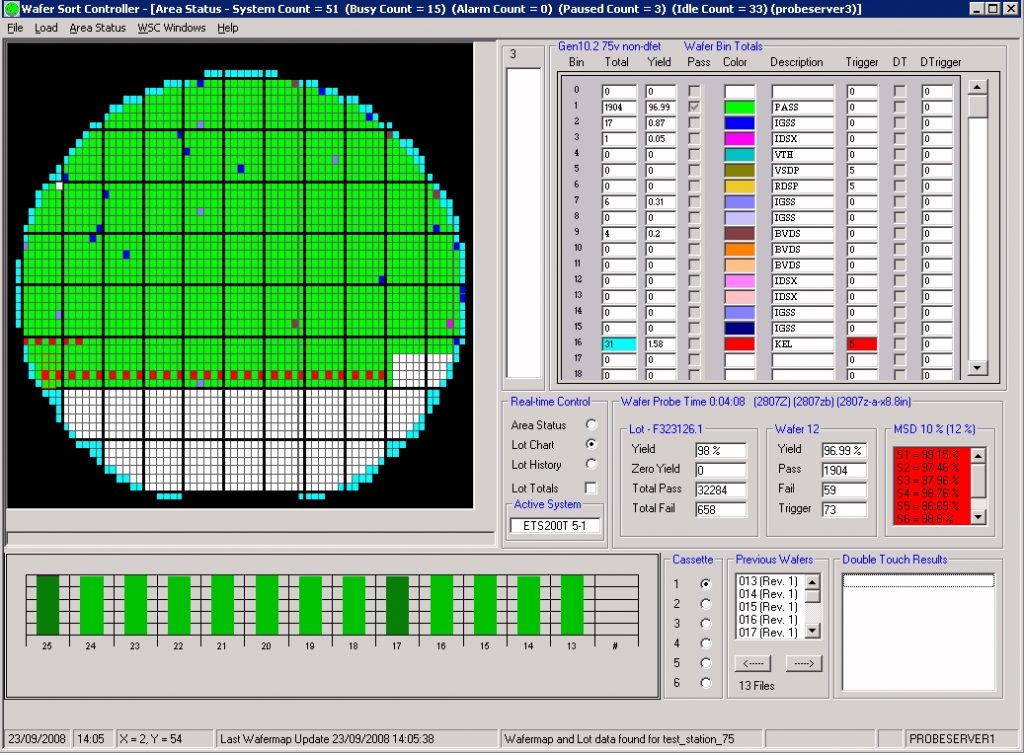

Real-Time Wafer Mapping

The WSC provides a real-time graphical wafer map display of the test results in full colour, with zoom options. Special features can be enabled to overlay the reticle shots and probe card configuration information onto the wafer map to aid in the early detection of process, tester hardware, and probe card problems.

The real-time wafer maps also provide the wafer bin results along with wafer and lot yield and trend information, allowing the user to keep track of exactly how the lot is performing, as shown in the examples below.

Off-Line Inking

The WSC provides flexibility by supporting in-line, off-line and post-probe inking.

In-line inking can be done either during probing or immediately after probing the wafer.

Off-line inking is an important feature to help maximise tester usage. A standalone prober is set-up and used specifically for inking. Firstly, the wafer/lot is set-up and probed via the WSC on the appropriate test station. Once probing is complete the wafer/lot can be transferred to the ink station for inking. The WSC provides the user with an easy to use intuitive interface enabling the automatic set-up and retrieval of wafer/lot results to be used for inking.

Inkless

The WSC offers full integration with Optical Character Recognition (OCR) systems to ensure wafer integrity. Intelligent routines are used to ensure reference die integrity thus enabling the support of inkless wafer sort.

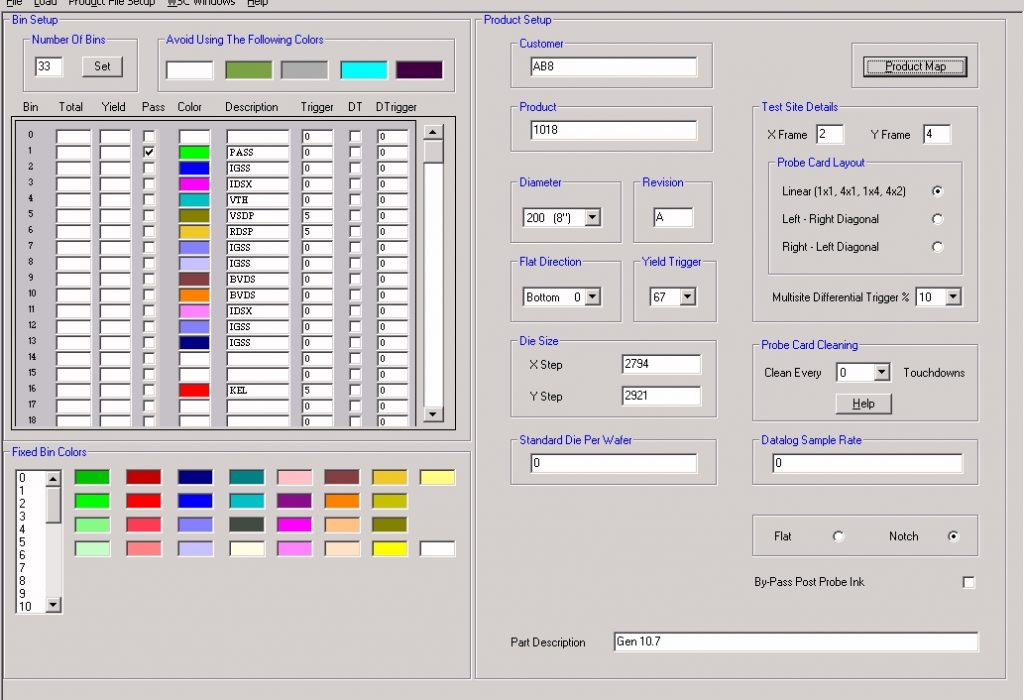

Multi-Site Probing

The WSC supports multi-site probing using the standard linear, rectangular and diagonal configurations.

Multi-site probing is enabled via the product specific control map where the required probe card configuration is defined. The user has the ability to define multi-site differential yield triggers to help identify and give early warning of any test or probe card related problems where there is significant yield difference between sites.

In addition, the WSC provides an ‘Intelligent Stepping‘ option to avoid probe card over-hang during multi-site probing.

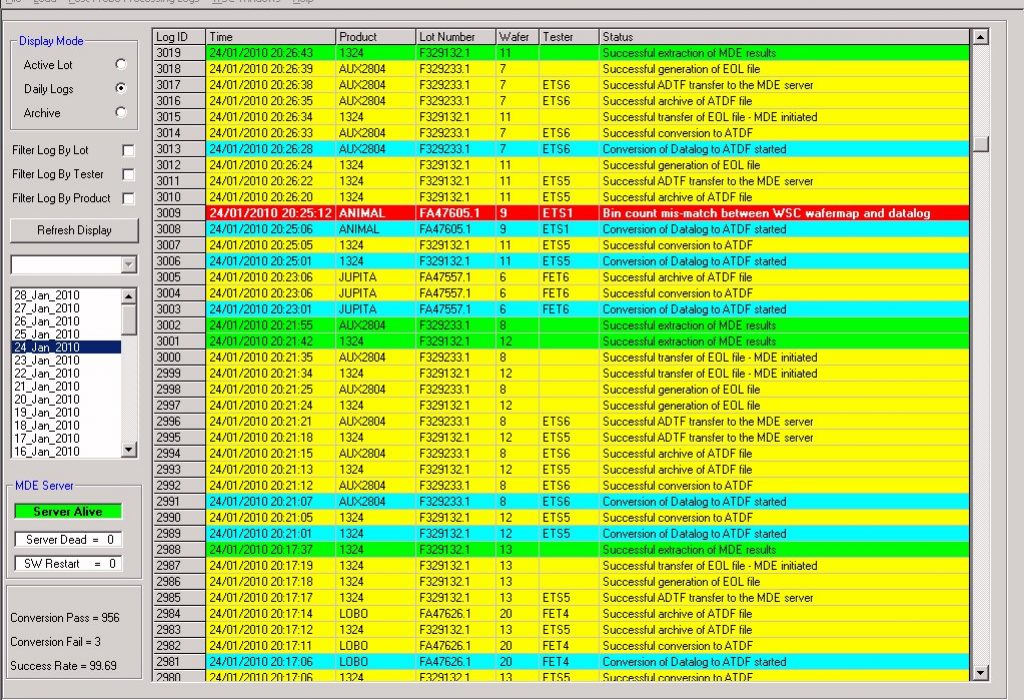

Real-Time Production Controls

The WSC provides extensive real-time yield management capabilities in the form of user definable production controls.

The user has the ability to define product specific yield and bin alarms that will trigger when the preset limits are reached enabling corrective action to be taken when these conditions occur, for example; probe tip clean/scrub, re-probe of specific bins, request for operator assistance, etc.

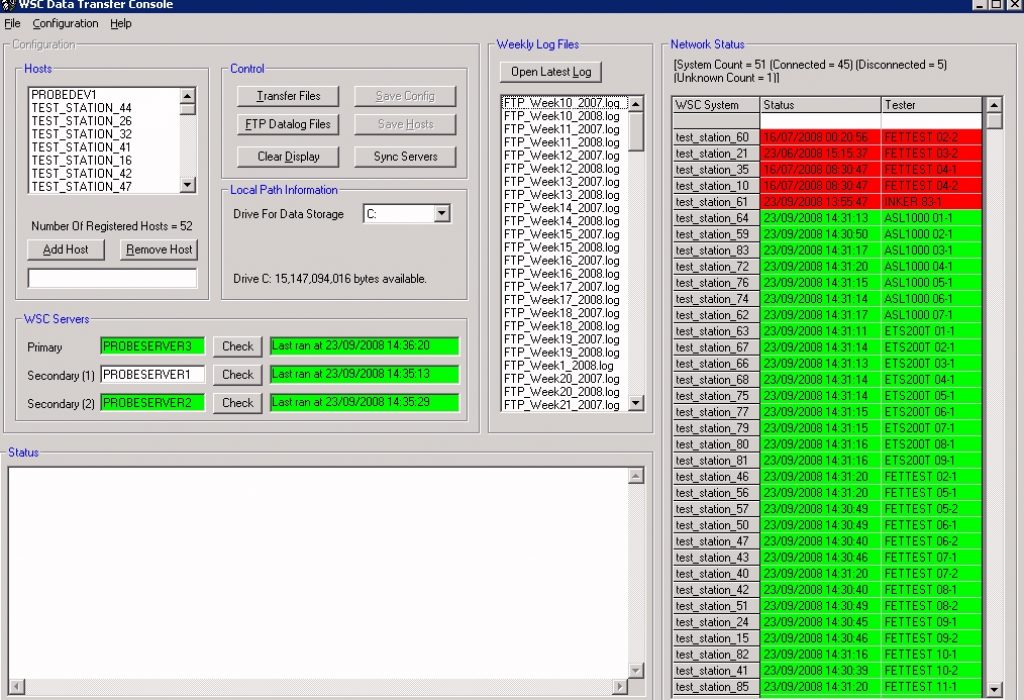

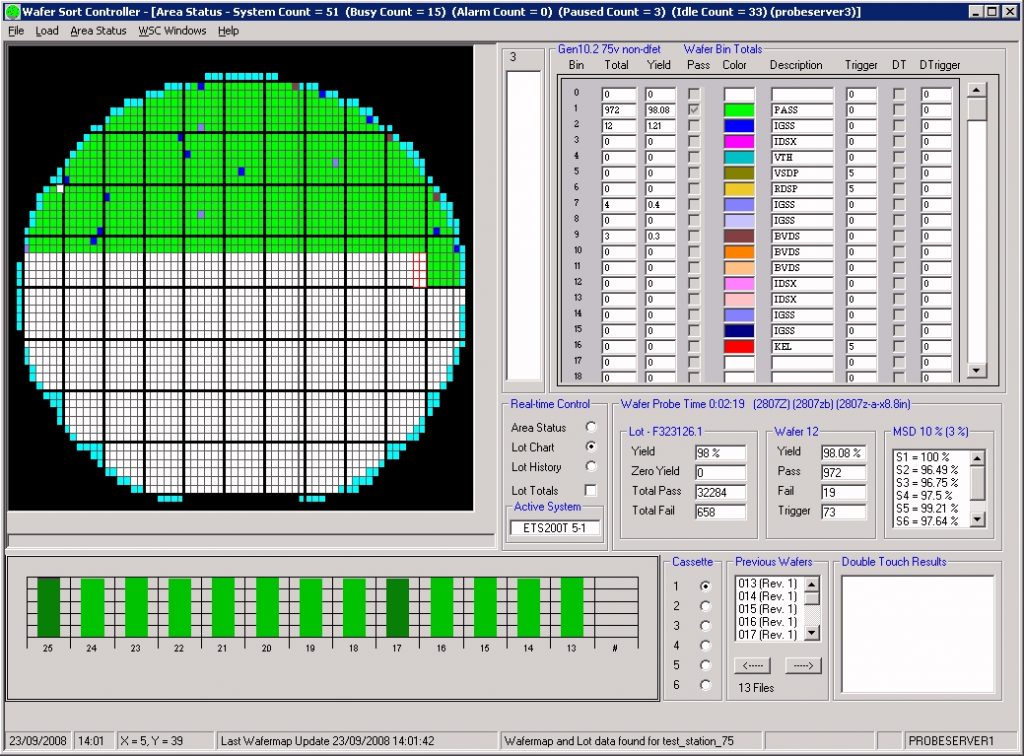

Real-Time Production Monitoring

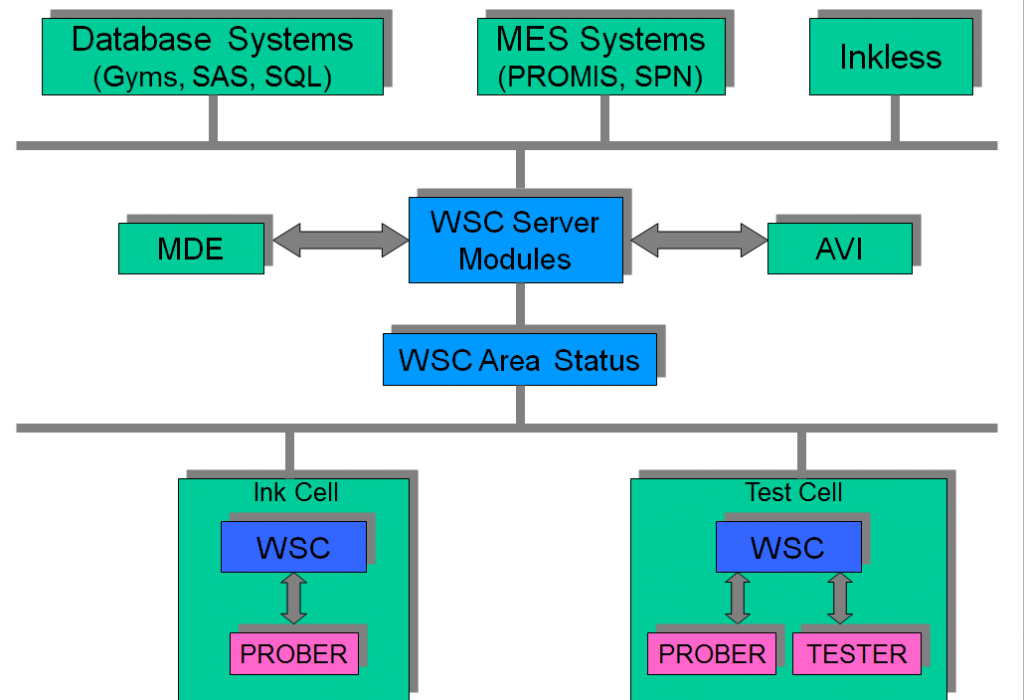

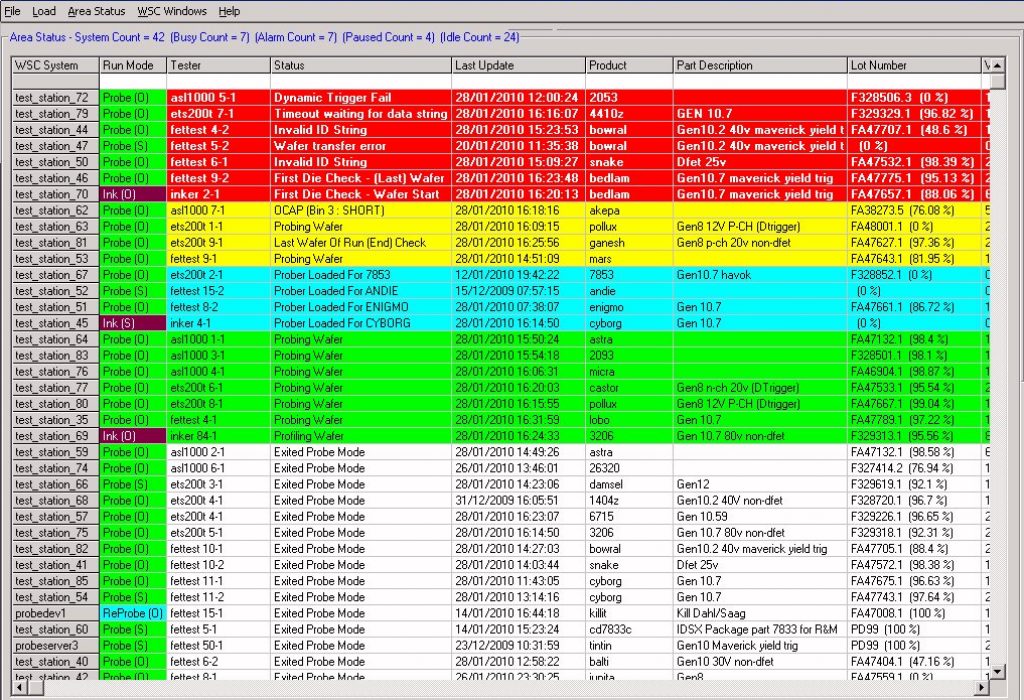

The WSC provides the ability to monitor in real-time the status of every production system on the network via the Area Status Tool.

The Area Status Tool provides a graphical display listing every test system and ink station on the network and it’s status using a traffic light colour-coded format, making interpretation of the results quick and easy.

The Area Status Tool also provides detailed information in relation to the product set-up, test program and hardware in terms of probe card and load board in use on each test system and ink station.

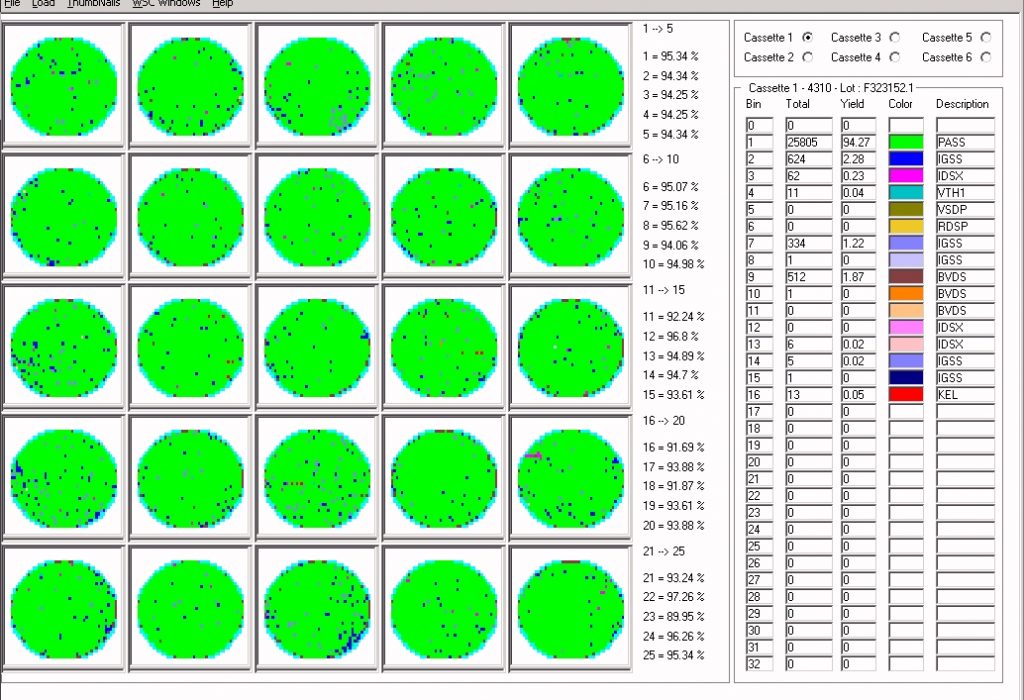

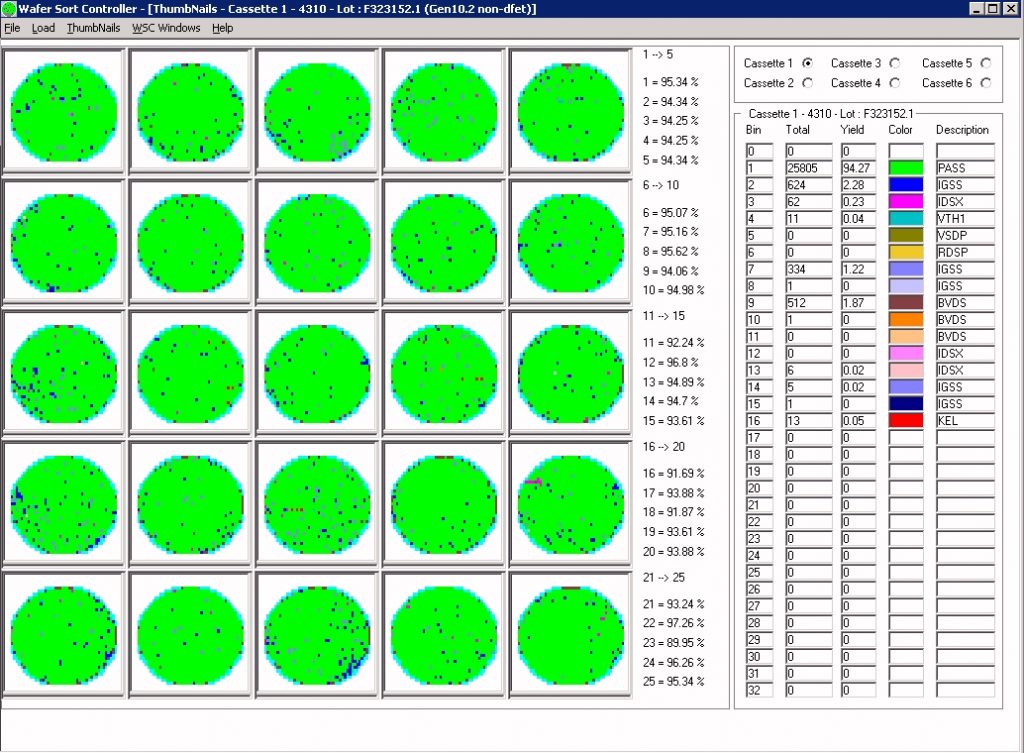

Wafer Thumbnails

The WSC provides the ability to review the wafer map results of all wafers in the lot via the wafer thumbnails feature.

Production personnel can use this feature to check the wafer maps and identify any potential probing problems that may need to be addressed, prior to moving the lot on to the next processing step.